Technology Location and

Directions Software Conferences Employment News

About

Introduction Periodic Multilayers Normal-Incidence Multilayer Optics Depth-Graded Multilayers Grazing-Incidence Multilayer Optics Aperiodic and Laterally-Graded

Multilayers Facilities

Facilities

Multilayer Deposition by Magnetron Sputtering

Custom facilities for multilayer fabrication and testing are located at RXO’s premises in New York City, including

the large magnetron sputtering system shown below in Figure 1. This

versatile coating system uses 50-cm-long planar, rectangular magnetron

cathodes, which can be arranged in several different configurations, depending

on the coating requirements. The circular geometry (i.e., planetary: rotation +

spin) shown at left in Figure 1 is

typically used to coat normal-incidence mirror

substrates, while the cylindrical geometry at right is best suited for

coating thin-glass mirror shells. A new linear

coating geometry is currently being developed for this coating system as well.

The linear geometry will enable the development of new techniques for

surface-figure correction of thin-glass shells using differential deposition

and erosion, in order to realize nested X-ray telescopes having improved

angular resolution for future NASA X-ray astronomy missions.

Figure 1. RXO's large magnetron sputtering

system uses 50-cm-long planar, rectangular cathodes that can be oriented

horizontally (left) or vertically (right), depending on the coating

requirements.

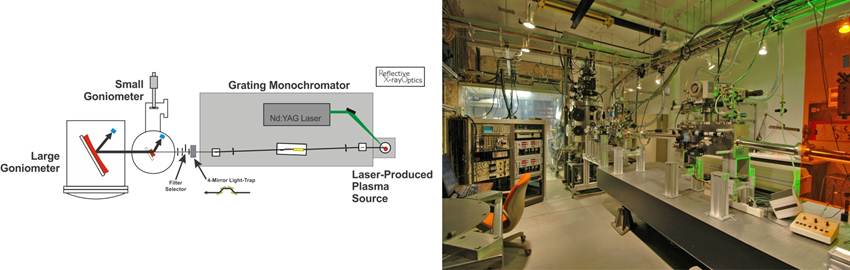

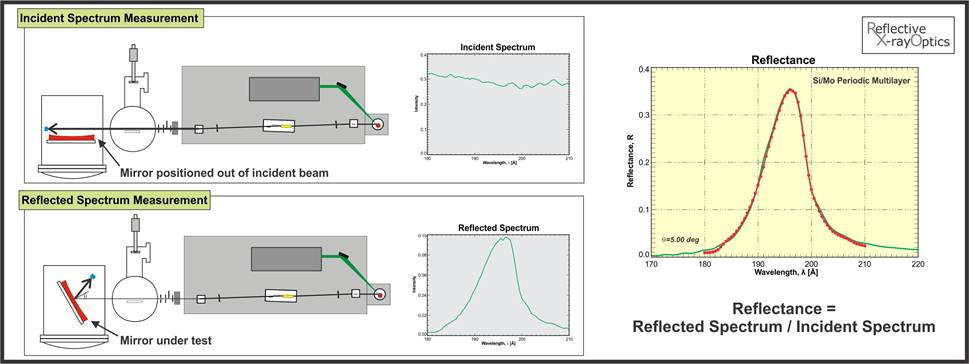

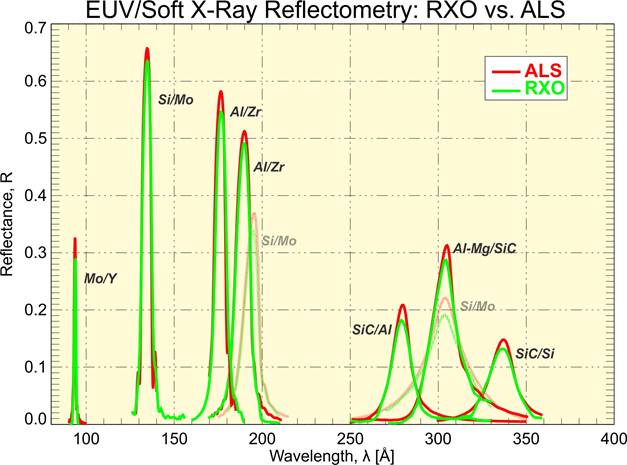

A variety of metrology tools are used for multilayer X-ray optics characterization at RXO, including X-ray reflectometry (8 keV) for thin-film structural characterization, wafer curvature for measuring film stress and thermal stability, and atomic force microscopy for measurement of film and substrate surface roughness. In addition, RXO has developed two unique facilities for “at-wavelength” characterization of multilayer optics: an EUV/soft X-ray reflectometer that uses a laser-produced-plasma light-source and a varied-line-space grating monochromator, illustrated in Figure 2 through Figure 4, and a hard X-ray reflectometer that uses a 160 kV X-ray tube and a CdTe energy-sensitive detector, illustrated in Figure 4 and Figure 5.

EUV/Soft X-Ray Reflectometer

Figure 2. RXO's laser-plasma-based reflectometer is used for at-wavelength characterization of multilayer optics in the soft X-ray and EUV bands. The large goniometer, which is housed in a soft-wall clean room, has 7 degrees of freedom (X,Y,Z, φ, χ, ϴ and 2ϴ) and can be used to measure coating uniformity on substrates as large as ~30 cm in diameter.

Figure 3. EUV and soft X-ray reflectance measurements of multilayer optics are made by dividing the measured reflected spectrum by the measured incident spectrum.

Figure 4. The wavelength scale of RXO's EUV

reflectometer is calibrated to Beamline 6.3.2 at the

ALS (courtesy of E. Gullikson), using 'standard'

multilayer samples that are measured at both facilities. Systematic errors in

the RXO reflectometer unfortunately result in

somewhat reduced peak reflectance values relative to those measured at the ALS.

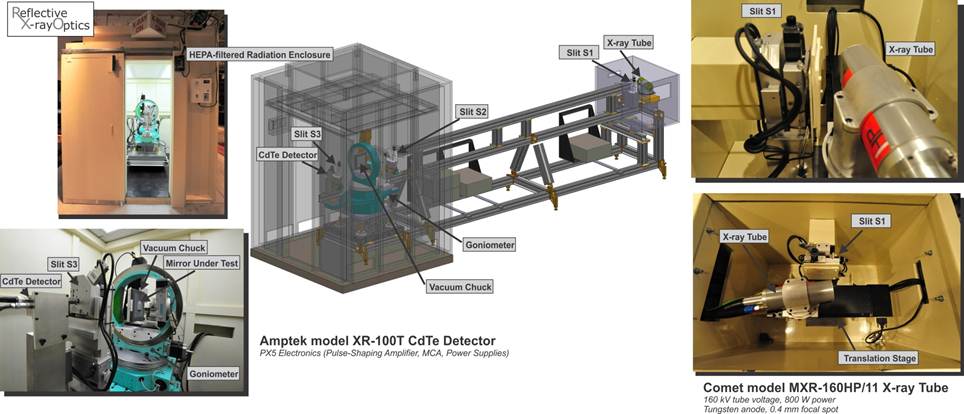

Hard X-ray Reflectometer

Figure 5. RXO's hard X-ray reflectometer comprises a 160 kV X-ray tube (Comet), three sets of 10-mm-thick W slits (JJ X-ray), a Huber goniometer with 5 degrees of freedom (Y,Z, χ, ϴ and 2ϴ), and a CdTe energy-sensitive detector (Amptek).

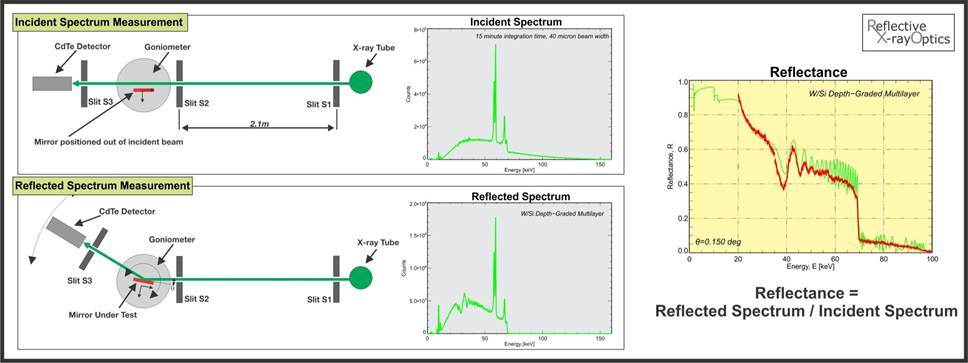

Figure 6. Hard X-ray reflectance measurements of multilayer optics are made by dividing the measured reflected spectrum by the measured incident spectrum.

Introduction Periodic Multilayers Normal-Incidence Multilayer Optics Depth-Graded Multilayers Grazing-Incidence Multilayer Optics Aperiodic and Laterally-Graded

Multilayers Facilities

© 2013 Reflective X-ray Optics LLC, All Rights

Reserved